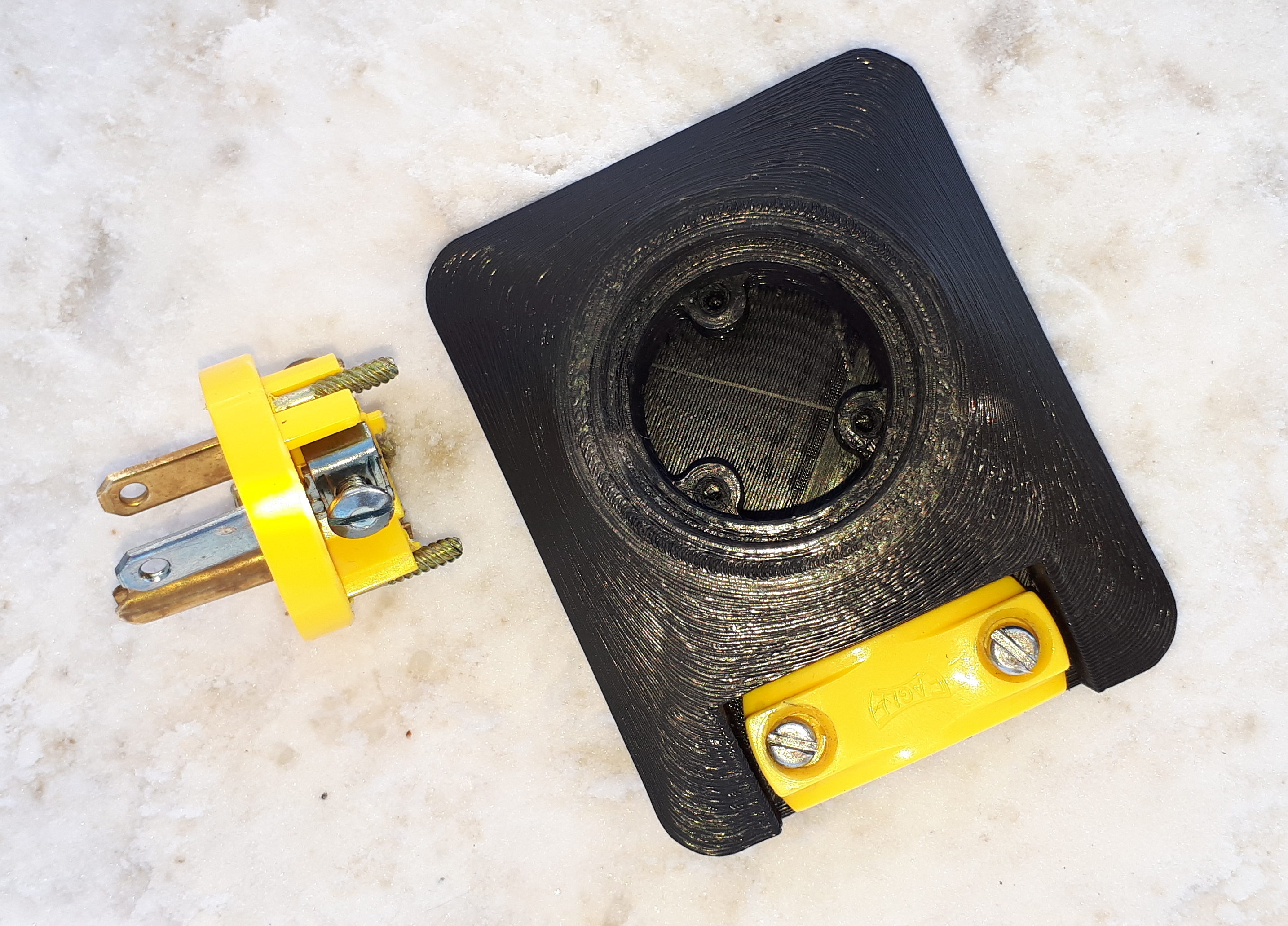

In order to start after -30C nights most cars around here have block heaters. Usually the plugs hang out from a radiator slot or just from under the hood. So in that-30C you have to hold the male end and hold the female end while wrangling a -30C stiff cable, while wearing mittens if you have any sense. I wanted the cord to be a bit tidier on the car, and make it so that plugging in is a one-handed thing that can be done more easily with mitts on. So, I took an existing plug and build a  new body for it. I have done 3d modelling before, but this was my first exposure to Autodesk’s Fusion 360. It is the nicest 3d modelling software I have used so far – very easy transition from other tools I have used and it just works. I feel like a total sell-out to use it instead of an open source product like FreeCAD, but it’s like I tried crack, there is no going back.

new body for it. I have done 3d modelling before, but this was my first exposure to Autodesk’s Fusion 360. It is the nicest 3d modelling software I have used so far – very easy transition from other tools I have used and it just works. I feel like a total sell-out to use it instead of an open source product like FreeCAD, but it’s like I tried crack, there is no going back.

A friend 3d printed the model for me, we installed it on Friday. The temperature was only -11C and sunny, but with a bit of wind. It was not optimal for playing with small parts and bare hands, but we got it done. For now the setup works, but it will be interesting to see how well the body and the silicon glue pad I used to hold it on will hold up. Generally gluing things in -11C is not a good idea, but this pad did better than I expected.